Chapter 5: Water Applications

Click on the topics below to view more information on the best practices for Allan Block segmental retaining wall design for residental and commercial applications.

5.1 Below grade water management plan for water application walls.

-

When more than incidental groundwater is known to move through the retained soils.

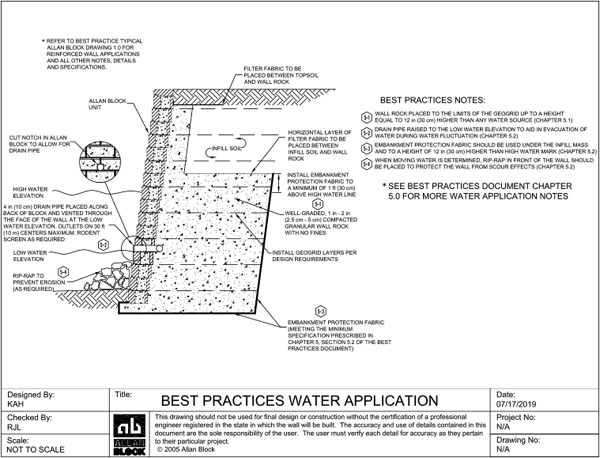

- The wall rock should be placed to the limits of the geogrid lengths up to a height equal to 12 inches (30 cm) higher than any water source.

5.2 When a wall is constructed to be a water application such as in a lake, stream or detention basin.

- The wall rock should be placed to the limits of the geogrid lengths up to a height equal to 12 inches (30 cm) higher than the determined high water mark. If the high water mark is unknown, the entire infill zone should be constructed with wall rock.

- The drain pipe should be raised to the low water elevation to aid in the evacuation of water from the reinforced mass as water level fluctuates.

-

Embankment protection fabric should be used under the infill mass and up the back of the infill mass to a height of 12 inches (30 cm) higher than the determined high water mark.

- Embankment protection fabric is used to stabilize rip rap and foundation soils in water applications and to separate infill materials from the retained soils. This fabric should permit the passage of fines to preclude clogging of the material. Embankment protection fabric shall be a high strength polypropylene monofilament material designed to meet or exceed typical NTPEP specifications; stabilized against ultraviolet (UV) degradation and typically meets or exceeds the values in Table 2.

- For walls having moving water or wave action, natural or manufactured rip-rap in front of the wall to protect the toe of the wall from scour effects is recommended.

| Mechanical Property | Determination Method |

|---|---|

| Tensile Strength = 225 lbs/in (39.4 kN/m) | ASTM D-4595 |

| Puncture Strength = 950lbs (4228 N) | ASTM D-6241 |

| Apparent Opening Size (AOS) = U.S. Sieve #70 (0.212 mm) |

ASTM D-4751 |

| Trapezoidal Tear = 100 lbs (445 N) | ASTM D-4533 |

| Percent Open Area = 4%) | COE-02215 |

| Permeability = 0.01 cm/sec | ASTM D-4491 |

Table 2: Embankment Protection Fabric Specifications