Chapter 3: Water Management - Typical

Click on the topics below to view more information on the best practices for Allan Block segmental retaining wall design for residental and commercial applications.

3.1 Identify localized water sources such as storm drains and drop structures. Consult with Project Site Civil Engineer to ensure that water will not be introduced into the reinforced mass. Consider excess irrigation or natural groundwater sources.

-

Utilize Water Management Section 3 in the Allan Block Spec Book.

-

Surface drainage

- Must drain away from the top and bottom of the wall.

- Slopes above walls should have swales placed above so water is not allowed to flow over the top of the wall.

- During construction, Surface water must not be allowed to pond or be trapped in the area above the wall or at the toe of the wall. Surface water must be directed away from partially constructed walls at the end of each day’s construction.

- Provisions, such as check valves, to prevent flooding from broken lines or heads must be put in place to stop over irrigation above walls.

-

Surface drainage

- Additional wall rock should be added around all storm drains and drop structures to aid in draining any areas of the pipe that may leak.

- If there are any utilities within the reinforcement zone, place gravel around them to generate good compaction levels.

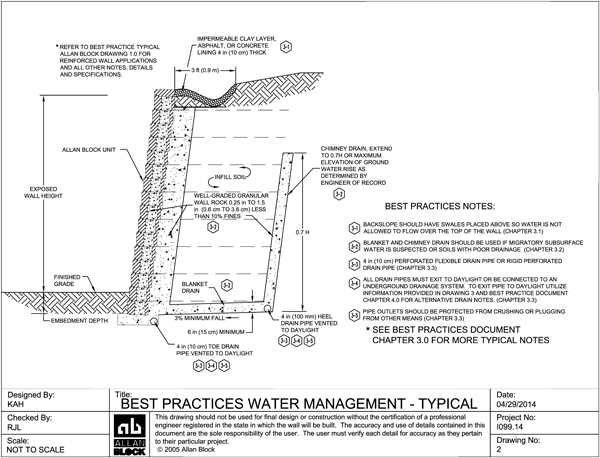

Figure 3-1: Surface Water Management

3.2 Use a combination of blanket and chimney drains

- If site soils are used that do not have granular characteristics, a chimney and blanket drain should be considered to ensure the infill mass stays as dry as possible. Unless otherwise directed by the geotechnical engineer, a blanket and chimney drain should be used when infill soils have a less than 30 degree friction angle when determined without the use of cohesion.

- If migrating subsurface water is on the site a chimney and blanket drain should be used.

- See Allan Block Chimney and Blanket Drain detail above.

- Drain material to be consistent with wall rock material. For more information on wall rock material see Chapter 2 Typical Wall Construction.

- Manufactured chimney and blanket drains to be approved by the geotechnical and/or the local engineer of record prior to use.

3.3 Location, type, and venting of drain pipes.

- Utilize Water Management Sections 1.4 and 1.5 in the Allan Block Spec Book.

- 4 in (10 cm) perforated flexible drain pipe or rigid perforated pipes are recommended.

- When a rigid perforated pipe is used, it should be placed with holes down.

-

All drain pipes must exit to daylight or be connected to an underground drainage system. Use Allan Block Alternate Drain detail for examples of venting to daylight.

- It is recommended that a minimum 1% gradient be maintained on the placement of the pipe with outlets on 50 ft (15 m) centers, or 100 ft (30 m) centers if the pipe is crowned between the outlets.

- It is recommended that all pipe outlets be configured to be protected from crushing or plugging from other means.

- For terraced applications, the toe and heel drains shall be routed as to not exit on the lower terraces. Drainpipes shall be extended to provide a path for water to be channeled away from the wall structure. Pipes at exit locations shall be marked to facilitate identification of where water is draining from.

- Drain pipes exiting to daylight through the wall should be installed with rodent screen to prevent nesting within the pipe. Cut adjoining block to allow for installation of a manufactured drain cover. Alternatively, Wall Drain Pro could be used without the requirement of cutting block. See more information here on Wall Drain Pro.

3.4 Above grade water management plan and finishing of the compacted soil mass.

- Surface water that cannot be diverted from the wall must be collected with surface drainage swales and drained laterally in order to disperse the water around the wall structure. Construction of a typical swale system shall be in accordance with Water Management - Typical Drawing No. 2.0 above. Also see Chapter 12 for further discussion on above wall considerations.