Chapter 7: Geogrid Reinforcement Requirements, Corner and Radius Design Practices

Click on the topics below to view more information on the best practices for Allan Block segmental retaining wall design for residental and commercial applications.

7.1 Certification to ensure proper materials for the geogrid reinforcement. Most geogrids used for soil reinforcement are manufactured from polyester fiber. To ensure a high quality product, use a geosynthetic reinforcement that has obtained an NTPEP Report.

- There are many different international manufacturers that are supplying geogrid reinforcement, and they are not all equal. It is important to understand what influences the durability of the geogrid. The U.S. Federal Highway Administration identified three key factors:

- Soils that have a pH of 10 or more represent an environment that could potentially degrade the geogrid faster especially in the presence of sufficient water.

- Polyester molecular weight – the size of the polymer molecule has a significant influence on the chemical durability.

- Polyester carboxyl end group (CEG) – grids are less susceptible to degradation when they have fewer CEG in their molecular structure.

- Establish minimum requirements when using polyester geogrids. CMHA adopted the guidelines that the FHWA set for geogrid reinforcement. All polyester geogrids submitted for approval must be made of polyester fiber that meets the following specifications:

- Molecular weight greater than 25,000 g/mol

- Caboxyl End Group less than 30 mmol/Kg

- The certification, obtained from the geogrid manufacturer, must originate from the actual manufacturer of the fiber to show conformance with the specification.

- Designer must consider soils that have a pH of 10 or more represent an environment that could potentially degrade the geogrid faster especially in the presence of sufficient water and may require additional design criteria.

7.2 Proper orientation of grid and placement.

- Typical commercial geogrid is uniaxial and strong in the roll direction and should be placed in sheets perpendicular to the wall facing.

-

Utilize Section 2 – Part 3.3 Geogrid Installation in the Allan Block Spec Book.

- Cut geogrid to designed embedment length and place on top of the Allan Block units to the back edge of the raised front lip or within 1 in (2.5 cm) of the retaining wall face when using AB Fieldstone.

- Extend away from wall approximately 3% above horizontal on compacted infill soils.

- For straight walls, placement of adjacent sheets of geogrid should be side-by-side without any overlap. For walls with corners or curves the following are the best practice method of placement:

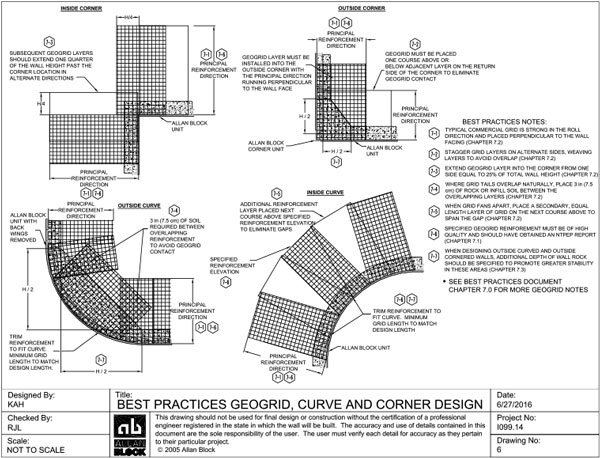

- For outside corners, to avoid overlapping grid layers, grids should be stagger by one course on either side of the corner, weaving the strong direction from bottom to top of wall. See Allan Block standard detail 10 in Allan Block Spec Book.

- For inside corners, extend the geogrid layer into the corner from one side a distance equal to 25% of the total wall height. Alternate extended geogrid layer from side to side per course to create a geogrid weave as wall is built. See Allan Block standard detail 9 in Allan Block Spec Book.

- For outside curves, where grid tails overlap naturally, place roughly 3 in (7.5 cm) of wall rock or infill soil between the overlapping layers. See Allan Block standard detail 12 in Allan Block Spec Book.

- For inside curves, where grid layers fan apart, place a secondary, equal length, layer of grid on the next course above the fanned gap. See Allan Block standard detail 11 in Allan Block Spec Book.

Figure 7-1: Grid Location

7.3 Wall rock design for corners and curved walls.

-

When designing curved and radius wall segments the designer should provide details to the installer for wall rock placement.

- For inside curved and inside cornered walls, the minimum wall rock specified should follow Section 6.4 (paragraph a) and Section 8.2 for Tall Wall applications.

- For outside curved and outside cornered walls, additional depth of wall rock should be specified to promote greater stability in these areas. Additional depth of wall rock is dependent on the total height of the wall and should be a minimum of H/2 as detailed in Drawing No. 6 on the top of this page.